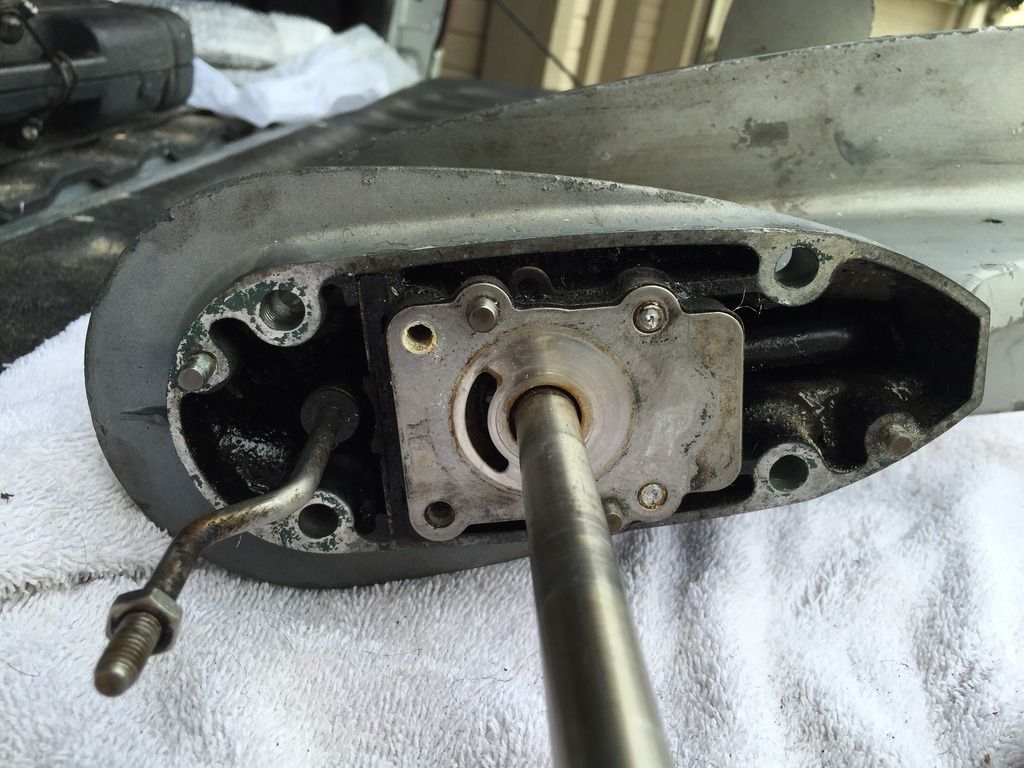

15 HP 2 stroke Yammie from the early 1980s. The two back bolts that hold the impeller housing have sheared off causing me to say "Shoot" real loud.

Neighbor ran over to see what all the ruckus was and he said they will never come being salted in (Dad ran this in salt water a lot.)

We started wondering if they are really needed; after all, if a little water gets in the lower end gear oil is sealed.

Then another guy walks up and says to simply drill them out and JB Weld in a bolt that has the head cut off and use a nut. Hmmmm, that might work.

What say you?

[Edited on 3-20-2016 by Santiago]