monoloco

Elite Nomad

Posts: 6667

Registered: 7-13-2009

Location: Pescadero BCS

Member Is Offline

|

|

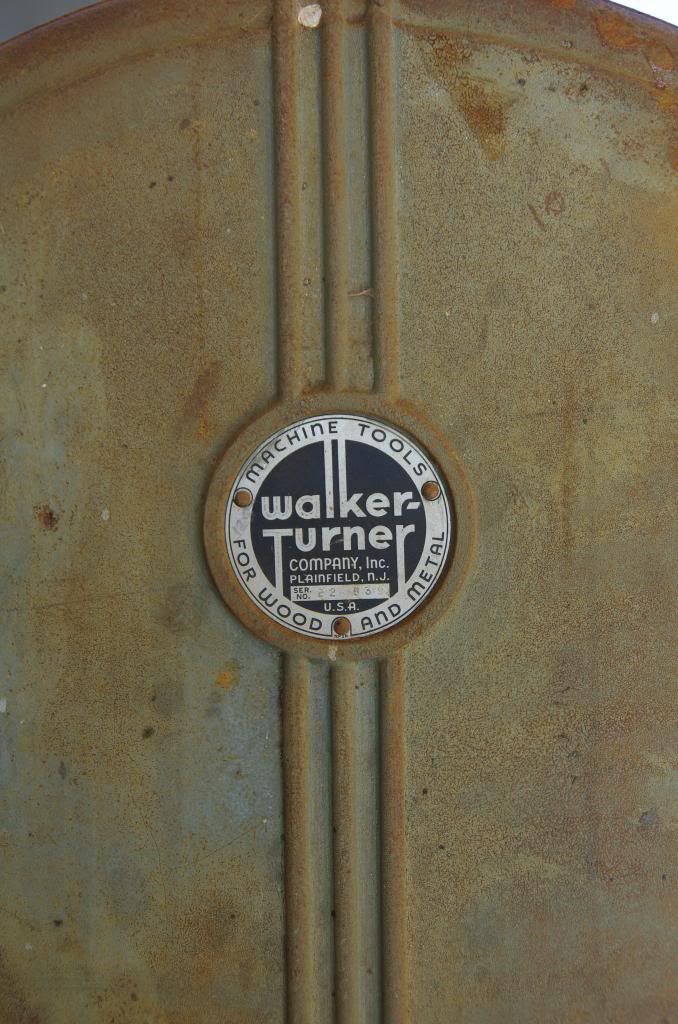

Repairing Cast Iron

I broke the cast iron bracket that holds the belt guard on my mid-1940's Walker Turner bandsaw. Might not seem like a big deal, but for me it was like

smashing the grill on a 57 Nomad. What's the best way to repair cast iron? Brazing? Epoxy? Here's some photos:

"The future ain't what it used to be"

|

|

|

woody with a view

PITA Nomad

Posts: 15939

Registered: 11-8-2004

Location: Looking at the Coronado Islands

Member Is Offline

Mood: Everchangin'

|

|

braze it!

|

|

|

taoswheat

Junior Nomad

Posts: 73

Registered: 11-29-2007

Location: Taos, NM USA

Member Is Offline

|

|

I have had pretty good luck on cast iron with my MIG and regular mild steel wire. It is not the recommended method but it has worked for me.

|

|

|

DENNIS

Platinum Nomad

Posts: 29510

Registered: 9-2-2006

Location: Punta Banda

Member Is Offline

|

|

I might consider taking it off, if possible, and making a new one out of steel...or aluminum.

"YOU CAN'T LITTER ALUMINUM"

|

|

|

55steve

Senior Nomad

Posts: 857

Registered: 4-24-2006

Location: Warner Springs, CA

Member Is Offline

|

|

I have used my MIG many times to weld cast iron - the trick is to preheat the cast to around 500-600 degrees and have at it. It may actually work

better with a flux-cored wire rather than regular solid wire with gas.

| Quote: | Originally posted by taoswheat

I have had pretty good luck on cast iron with my MIG and regular mild steel wire. It is not the recommended method but it has worked for me.

|

|

|

|

dtbushpilot

Ultra Nomad

Posts: 3290

Registered: 1-11-2007

Location: Buena Vista BCS

Member Is Offline

Mood: Tranquilo

|

|

From your pictures I can't tell where it goes or how it holds the guard so I'll give a general reccomendation:

Cast iron varies greatly in quality and repairability. Typically older American made machinery is pretty good stuff and responds well to electric

welding (stick, mig, tig, etc.) when done properly.

If appearance isn't a big issue and it isn't an important structural member, brazing by someone who knows how to do it would be a good option. Brazing

is also a better process for lesser quality cast iron or when the quality can't be easily determined

If it were an important structural member (i.e. holding something heavy over your head) I would reccomend replacing it or making a new one out of mild

steel.

Keep in mind that the original part broke, a repair on cast iron won't be as strong as the original part.

"Life is tough".....It's even tougher if you're stupid.....

|

|

|

monoloco

Elite Nomad

Posts: 6667

Registered: 7-13-2009

Location: Pescadero BCS

Member Is Offline

|

|

The bracket is a crescent shaped affair that only holds that deco looking belt guard which hinges from the top of the crescent. I think I'll take it

to a fairly talented fabricator that I know and see if he can braise it.

"The future ain't what it used to be"

|

|

|

wessongroup

Platinum Nomad

Posts: 21152

Registered: 8-9-2009

Location: Mission Viejo

Member Is Offline

Mood: Suicide Hot line ... please hold

|

|

Damn you're hard on tools ...

Worry about someone "picking" it up and walking off with it

[Edited on 11-11-2013 by wessongroup]

|

|

|

rogbag

Nomad

Posts: 124

Registered: 8-27-2008

Location: Los Barriles, BCS

Member Is Offline

|

|

It can be welded, but the broken pieces have to be brought up to a high temperature first. And it takes a special welding rod. Or it can be brazed. I

suggest that you ask the local how he welds cast iron before you give it to him to be welded. If the guy doesn't talk about heating it up first then

you should find another welder until you find one that answers the question correctly.

|

|

|

RnR

Senior Nomad

Posts: 837

Registered: 5-1-2010

Member Is Offline

|

|

More than you ever wanted to know....

Lincoln Arc Welders -- Welding Cast Iron

|

|

|

monoloco

Elite Nomad

Posts: 6667

Registered: 7-13-2009

Location: Pescadero BCS

Member Is Offline

|

|

Thanks for that.

"The future ain't what it used to be"

|

|

|