Santiago

Ultra Nomad

Posts: 3541

Registered: 8-27-2003

Member Is Offline

|

|

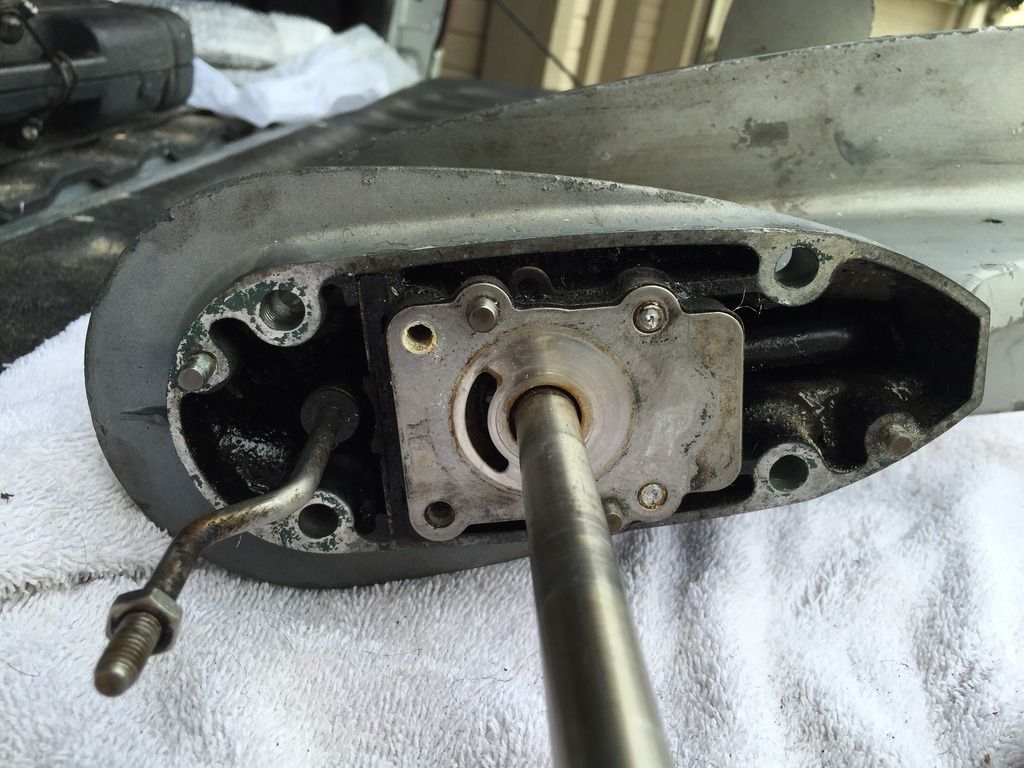

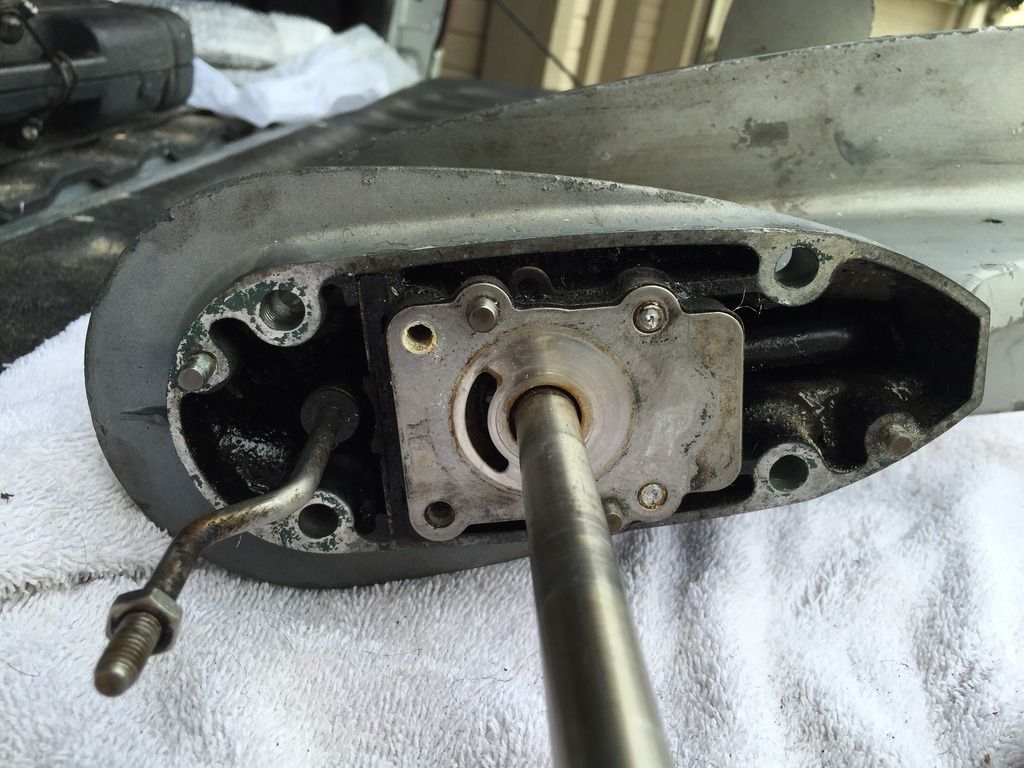

removing sheard bolts from aluminum lower end?

15 HP 2 stroke Yammie from the early 1980s. The two back bolts that hold the impeller housing have sheared off causing me to say "Shoot" real loud.

Neighbor ran over to see what all the ruckus was and he said they will never come being salted in (Dad ran this in salt water a lot.)

We started wondering if they are really needed; after all, if a little water gets in the lower end gear oil is sealed.

Then another guy walks up and says to simply drill them out and JB Weld in a bolt that has the head cut off and use a nut. Hmmmm, that might work.

What say you?

[Edited on 3-20-2016 by Santiago]

|

|

|

rts551

Elite Nomad

Posts: 6700

Registered: 9-5-2003

Member Is Offline

|

|

Use an easy out. then chase the threads with a tap.

|

|

|

Fernweh

Nomad

Posts: 444

Registered: 2-24-2011

Location: Centenario, BCS

Member Is Offline

|

|

Easy Out...it is only the name, it's never easy out, especially with salt water corrosion.

I would drill them out, starting in the center for sure, with a small bit first, and then go larger, step by step. If your lucky, you can peel out the

remaining threads.

Re-tap the the bores again or use a thread insert if needed.

Make it as nice and precise as possible, remember, you need to have the coolant water being pushed up all the way into the hot head

|

|

|

larryC

Super Nomad

Posts: 1499

Registered: 8-11-2008

Location: BoLA

Member Is Offline

|

|

I agree with rts, but along with the easy out you will probably have to use some heat. It looks like you could get a torch in there beside the broken

stud and heat the aluminum up some to help loosen the broken stud. You have to be very careful when you drill the stud to stay in the center of it.

Might also have to use a cobalt drill bit and start with a center punch and center drill. Not an easy repair. Is it a 6mm bolt? 6mm is a little

smaller than 1/4". Not much material to work with.

Good luck with it.

Off grid, 12-190 watt evergreen solar panels on solar trackers, 2-3648 stacked Outback inverters, 610ah LiFePo4 48v battery bank, FM 60 and MX60

Outback charge controllers, X-240 Outback transformer for 240v from inverters, 6500 watt Kubota diesel generator.

|

|

|

PaulW

Ultra Nomad

Posts: 3113

Registered: 5-21-2013

Member Is Offline

|

|

Use an ezout an break it off and then you have a real issue. EZouts break very easily and leave the hardened remains inside so you cannot use a

drill.

Based on your using it in salt I would grind it flat and drill it out and use the next size larger tap and bolt. If you are lucky you might even save

the original threads.

Irwin and Sears sell the reverse drill bit with a conical starter that probably will not break off it if the thing is really stuck. I would try that

tool before drilling. Still you need a flat surface and a center punch.

|

|

|

larryC

Super Nomad

Posts: 1499

Registered: 8-11-2008

Location: BoLA

Member Is Offline

|

|

One other method might be to remove the stainless water pump plate to give you a little more clearance and then take it to a good welding fabricator

and have them tig or mig weld a nut (on the inside of the nut) to the exposed broken stud and some heat and they may be able to get it out that way.

Just the heat from the tig/mig weld will probably be enough heat to break the salts loose that are holding the stud in place.

Off grid, 12-190 watt evergreen solar panels on solar trackers, 2-3648 stacked Outback inverters, 610ah LiFePo4 48v battery bank, FM 60 and MX60

Outback charge controllers, X-240 Outback transformer for 240v from inverters, 6500 watt Kubota diesel generator.

|

|

|

Bob and Susan

Elite Nomad

Posts: 8813

Registered: 8-20-2003

Location: Mulege BCS on the BAY

Member Is Offline

Mood: Full Time Residents

|

|

don't do it yourself...drive it over to a machine shop...bite the bullet

you ONLY get one chance not to "screw" this up

|

|

|

willardguy

Elite Nomad

Posts: 6451

Registered: 9-19-2009

Member Is Offline

|

|

where's captkw when we need him?

|

|

|

ncampion

Super Nomad

Posts: 1238

Registered: 4-15-2006

Location: Loreto

Member Is Offline

Mood: Retired and Loving it

|

|

If there's a little bit of the bolt protruding above the surface, which it looks like there might be, you can make a "centering jig" with a peice of

1/4" metal that bolts in place of the water pump plate. That let's you drill right down the center of the bolt. Otherwise it's very difficult to

drill in the center which is necessary to do it right. You may still need a thread insert when it's all done. I always use a little Anti-seize on SS

bolts that go into saltwater motors.

Living Large in Loreto. Off-grid and happy.

|

|

|

LancairDriver

Super Nomad

Posts: 1605

Registered: 2-22-2008

Location: On the Road

Member Is Offline

|

|

I own a machine shop and we do hundreds of sheared and broken bolts and taps in a year. From the picture it looks like you start with a sharp tip

punch to allow you to center a spot on the broken bolt to start drilling. This method uses the most common tools you may have available. Start with a

smaller drill and work up to a larger one. If you are able to open a hole large enough you will be left with a thin wall of the remainder of the bolt.

This can then be carefully chipped out with a small screwdriver without damaging the threads. Running a tap to chase the threads and clean them may be

necessary. An easy out would require a fairly well centered drilled hole and then an easy touch to work the easy out without breaking it and making

the problem worse. A good penetrating oil applied before any of this will help a lot with the corrosion sure to be there.

Some auto repair and machine shops have portable EDM (electrical discharge machine) to burn the bolt away which works the best if you have access to

this.

|

|

|

mtgoat666

Platinum Nomad

Posts: 20671

Registered: 9-16-2006

Location: San Diego

Member Is Offline

Mood: Hot n spicy

|

|

Quote: Originally posted by Santiago  |

15 HP 2 stroke Yammie from the early 1980s. The two back bolts that hold the impeller housing have sheared off causing me to say "Shoot" real loud.

Neighbor ran over to see what all the ruckus was and he said they will never come being salted in (Dad ran this in salt water a lot.)

We started wondering if they are really needed; after all, if a little water gets in the lower end gear oil is sealed.

Then another guy walks up and says to simply drill them out and JB Weld in a bolt that has the head cut off and use a nut. Hmmmm, that might work.

What say you?

[Edited on 3-20-2016 by Santiago] |

Take it to a machine shop!

I often amuse myself when I start a home DIY project and then break the widget, and end up taking the project to a professional to fix my mistake

|

|

|

dtbushpilot

Ultra Nomad

Posts: 3296

Registered: 1-11-2007

Location: Buena Vista BCS

Member Is Offline

Mood: Tranquilo

|

|

What LancairDriver said, have done it many times. If you don't have the tools or experience with them it would be best to take it to a machine shop

and save yourself a lot of grief.

"Life is tough".....It's even tougher if you're stupid.....

|

|

|

captkw

Ultra Nomad

Posts: 3850

Registered: 10-19-2010

Location: el charro b.c.s.

Member Is Offline

Mood: new dog/missing the old 1

|

|

Oops !

start by removing the "wear plate" that's the s/s the 4 bolts went thru..it will come with a gentel touch of a chisel...then grid the top of the bolts

as flat as you can without hitting the aluminum that is a sealing area..then Center punch in the very,very center of broken bolt..using a air drill..

drill completely thru bolt if possible but not more.. get a can of areokroil, stick in red tube and start soaking from both ends...now, you can start

driver larger and larger drill bits.. then decide how long you can soak and what size to drill up to.. hit the easy out in with a GooD "Whap" of a

small hammer.. Say Loud prayer and give it a try and you will get the feel for it.."Wish ya luck"ps reinstall with bolt coverd in a marine grease...

|

|

|

55steve

Senior Nomad

Posts: 857

Registered: 4-24-2006

Location: Warner Springs, CA

Member Is Offline

|

|

I usually just weld a nut onto the stud....the heat generated helps loosen it. This process may have to be repeated a few times but it always works

for me.

Don't use never-seize when reinstalling - marine grease is best - my friend (marine mechanic) swears that moly-based grease is the way to go though.

[Edited on 3-20-2016 by 55steve]

|

|

|

wessongroup

Platinum Nomad

Posts: 21152

Registered: 8-9-2009

Location: Mission Viejo

Member Is Offline

Mood: Suicide Hot line ... please hold

|

|

EDM (electrical discharge machine) ... they work sweet .. the true easy out ... thx LancairDriver

[Edited on 3-20-2016 by wessongroup]

|

|

|

Santiago

Ultra Nomad

Posts: 3541

Registered: 8-27-2003

Member Is Offline

|

|

Everyone's ignored the idea that came up to just forget about the back bolts; is that because it's stoooopid? Heh, prolly so.

|

|

|

larryC

Super Nomad

Posts: 1499

Registered: 8-11-2008

Location: BoLA

Member Is Offline

|

|

Quote: Originally posted by Santiago  | Everyone's ignored the idea that came up to just forget about the back bolts; is that because it's stoooopid? Heh, prolly so.

|

That would be my last choice. Weld a nut to the stud and it will probably come right out.

Off grid, 12-190 watt evergreen solar panels on solar trackers, 2-3648 stacked Outback inverters, 610ah LiFePo4 48v battery bank, FM 60 and MX60

Outback charge controllers, X-240 Outback transformer for 240v from inverters, 6500 watt Kubota diesel generator.

|

|

|

jayme

Newbie

Posts: 11

Registered: 10-8-2013

Location: B.C. Canada

Member Is Offline

|

|

Ditto to the welded nut. If the bolt is broke flush, weld a washer on the broken stud, then weld a nut to the stud. That is the fastest way, and if

that breaks off, the stud can be drilled

|

|

|

Udo

Elite Nomad

Posts: 6364

Registered: 4-26-2008

Location: Black Hills, SD/Ensenada/San Felipe

Member Is Offline

Mood: TEQUILA!

|

|

IF the bolts are not totally frozen in place, you may center-punch the bolt at dead center and drill in incremental sizes (sorry of the big word) with

a left-handed drill bit and the bolt may just come loose right away. However, in past experience, use WD40 or other penetrant (for obvious reasons the

bolts have to be in upright position) for at least 24 hours prior to attempting the drill method.

You can buy left-handed drill bits (good quality) if you google the word.

Udo

Youth is wasted on the young!

|

|

|